How Digital Automatic Coupling Works — Europe’s Freight System Upgrade

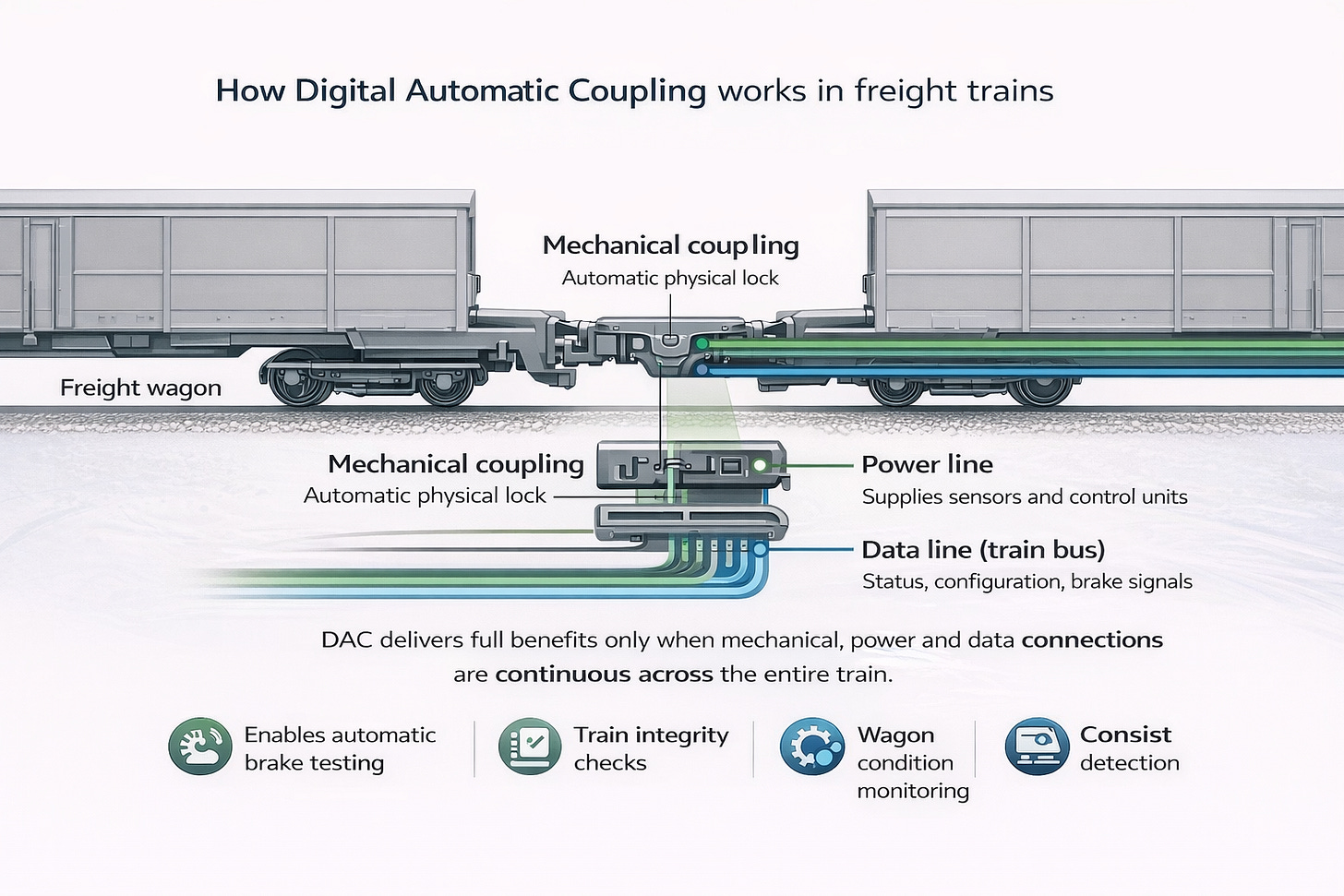

Digital Automatic Coupling (DAC) is often described as a single technical upgrade. In practice, it is a combined mechanical, electrical and digital system that changes how freight trains are assembled, powered and monitored.

The most obvious change is mechanical. When two wagons meet, the DAC head locks automatically, removing the need for staff to work between vehicles. This eliminates one of freight rail’s most time-consuming and safety-critical manual tasks.

What makes DAC different from traditional coupling systems is what happens at the same time. Alongside the mechanical lock, the coupler establishes interfaces for electrical power and digital data. These additional connections are what turn a physical coupling into a system-level upgrade.

Power along the entire train

One of DAC’s key features is a continuous electrical line running through the full length of the train. Today, most freight wagons operate without shared power. Sensors, where they exist, rely on batteries and are limited in both scope and reliability.

With DAC, wagons can draw power from the locomotive or a distributed onboard supply. This allows sensors, control units and communication devices to operate continuously. In operational terms, it enables permanent monitoring of components such as brakes, axle bearings and couplers rather than periodic or manual checks.

Power continuity is also what enables higher-level functions. Without it, DAC would remain a mechanical improvement with limited operational effect.

Data becomes part of the train

DAC also introduces a digital data line running through the train. Each wagon can transmit status information to the locomotive and onward to ground systems. Instead of isolated data points, the train functions as a single data environment.

Train composition checks change as a result. When wagons are added or removed, the system can identify the new consist automatically rather than relying on manual paperwork and visual confirmation.

Over time, operators expect this data layer to support predictive maintenance, faster fault localisation and more targeted interventions in yards and terminals.

Automatic brake testing

Brake testing is one of freight rail’s most labour-intensive procedures. Today, it usually requires staff to walk the full length of the train, visually checking brake application and release on each wagon.

With DAC and a powered data line, brake systems can be tested automatically. Sensors confirm brake response across the train, and results are verified digitally. This shortens preparation time and reduces operational risk, particularly for long trains assembled under tight pathing constraints.

Automatic brake testing is often cited as DAC’s most immediate operational benefit because it directly affects turnaround time and capacity use.

Why synchronisation matters

DAC delivers its full value only when deployed at scale. In mixed fleets, where some wagons are equipped and others are not, power and data continuity break at non-equipped vehicles. Operators are then forced back into hybrid procedures that retain many manual steps.

This makes DAC less a question of individual fleet upgrades and more a question of coordinated deployment across corridors and networks. Without alignment, benefits remain local rather than systemic.

From manual work to monitored operations

If viewed on its own, DAC can look like a technical detail. In daily operations, it changes how freight trains are handled. Manual coupling, visual inspections and walk-the-train procedures are reduced. Continuous monitoring and automated checks take their place.

The practical challenge is not developing the technology. It is aligning wagons, locomotives, terminals and operating rules so that the system saves time, reduces manual work and improves reliability across the freight network.